I.M.S. Precision Engineering Ltd produce a wide range of precision machined components for our clients, from prototyping and one-offs through to batch production. We offer fast response to all enquiries dealt by our team of experienced engineers, ensuring your components will be delivered both on time, and on budget.

EXPERIENCE

Our highly dedicated and experienced team work closely with our customers, assisting you in overcoming your engineering problems, and helping you bring your initial designs to fruition as finished products.

SKILLS

Operating from our fully-equipped engineering facility, we have the skills and capacity to undertake a wide range of precision engineering work for your business, ensuring that we fulfil all of your requirements.

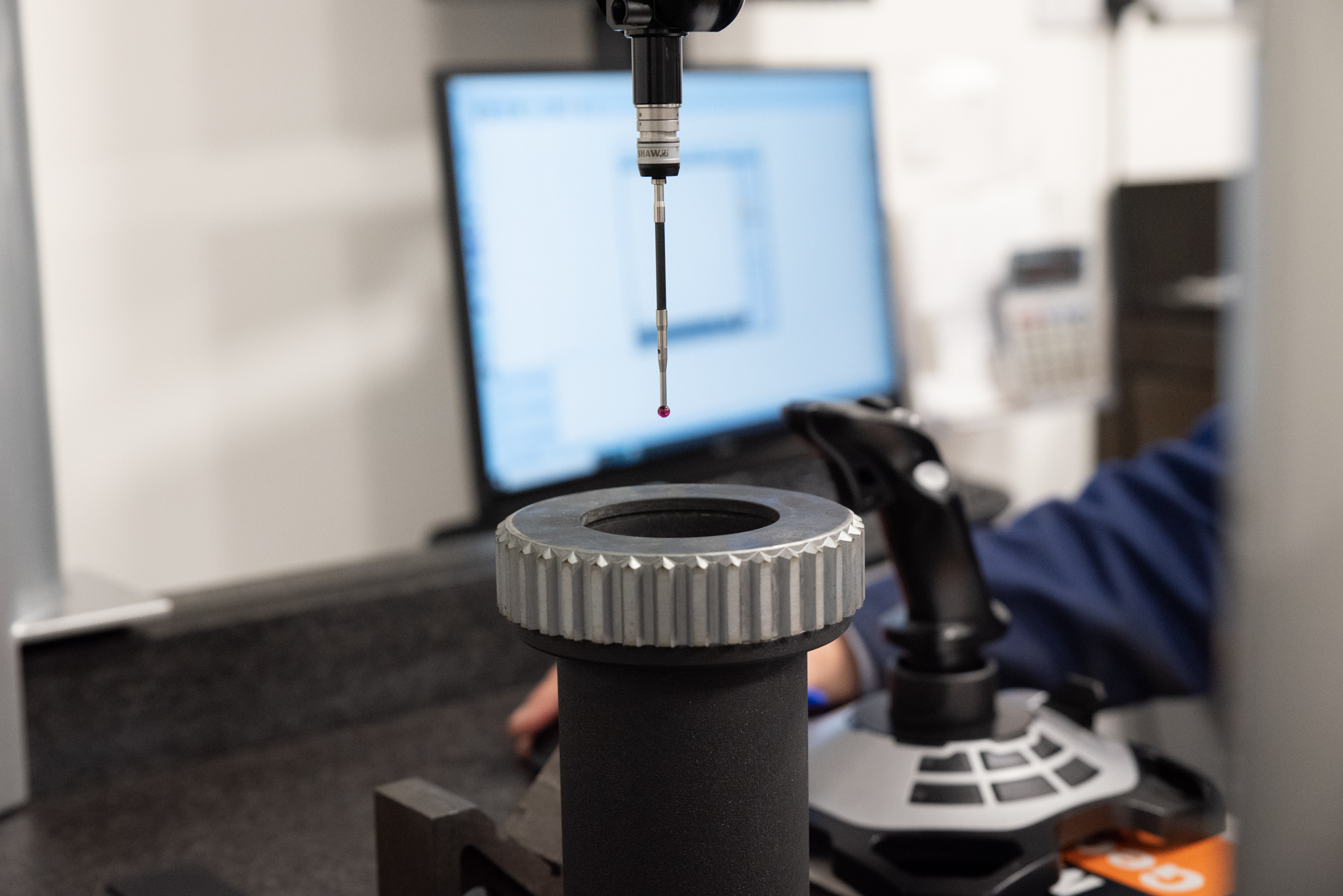

QUALITY

IMS are ISO9001:2015 accredited, having implemented a comprehensive Quality Management System (QMS). We carry out First Off, and Full Final Inspection, ensuring your parts meet your specifications every time, and can provide FAIR Reports, Certificates of Conformity and Full Material/Parts Traceability.

EXCELLENCE

Our mission is to provide a total engineering solution for customers requiring manufacturing excellence in precision engineering, often tackling difficult jobs other engineering companies avoid.

We Deliver

Flexible Production

IMS are flexible – we are able to manufacture anything from small to large prototypes, through to large production runs, meeting any deadlines you may have. IMS offer manufacturing solutions and can advise on choosing the right materials and processes, such as heat treatment and plating, managing the entire process, giving you complete peace of mind.

Technology At Work

Technology Driver – to do the job efficiently and correct you need modern machinery. We use only the best machinery available allowing us to produce quality products, and we have invested yearly in new machinery, software and tooling. We can deal with the entire process from print, to finished parts and assemblies.

Customer Experience

IMS have an excellent reputation based on working with companies across the U.K. and the world in many sectors. Our clients include: Defence, Medical, Prototyping, Composites, Motorsport and Special Purpose Machinery sectors.

Performance

IMS is a customer-focused company, guided by three principals: quality – delivering products right on specification; value – providing the best return on your investment; flexibility – meeting customer requirements, for new product development or components in full production.

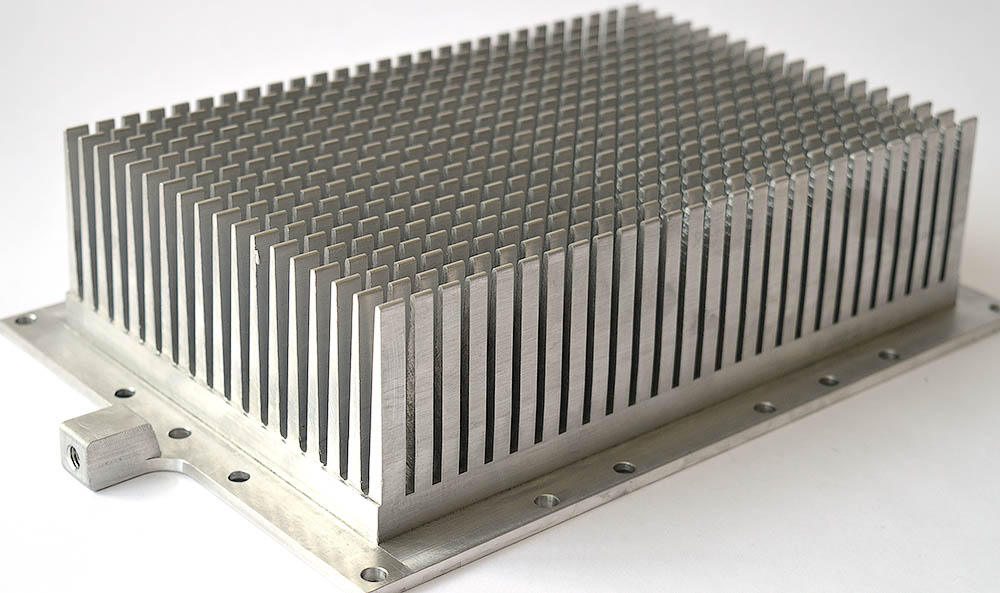

CNC Milling

We have CNC Milling machines with capacity up to 1000x500x500mm with 4th Axis Capability. We use the latest tooling technology with adaptive programming to achieve the highest quality components while reducing cycle times.

CNC Turning

We have CNC Lathes with capacity up to 500mm Diameter and 650mm long. We have Milling & Y-Axis capability for getting complex machined components off in one operation. Our CNC Lathes also have automatic running capability with bar-feeders for high productivity.

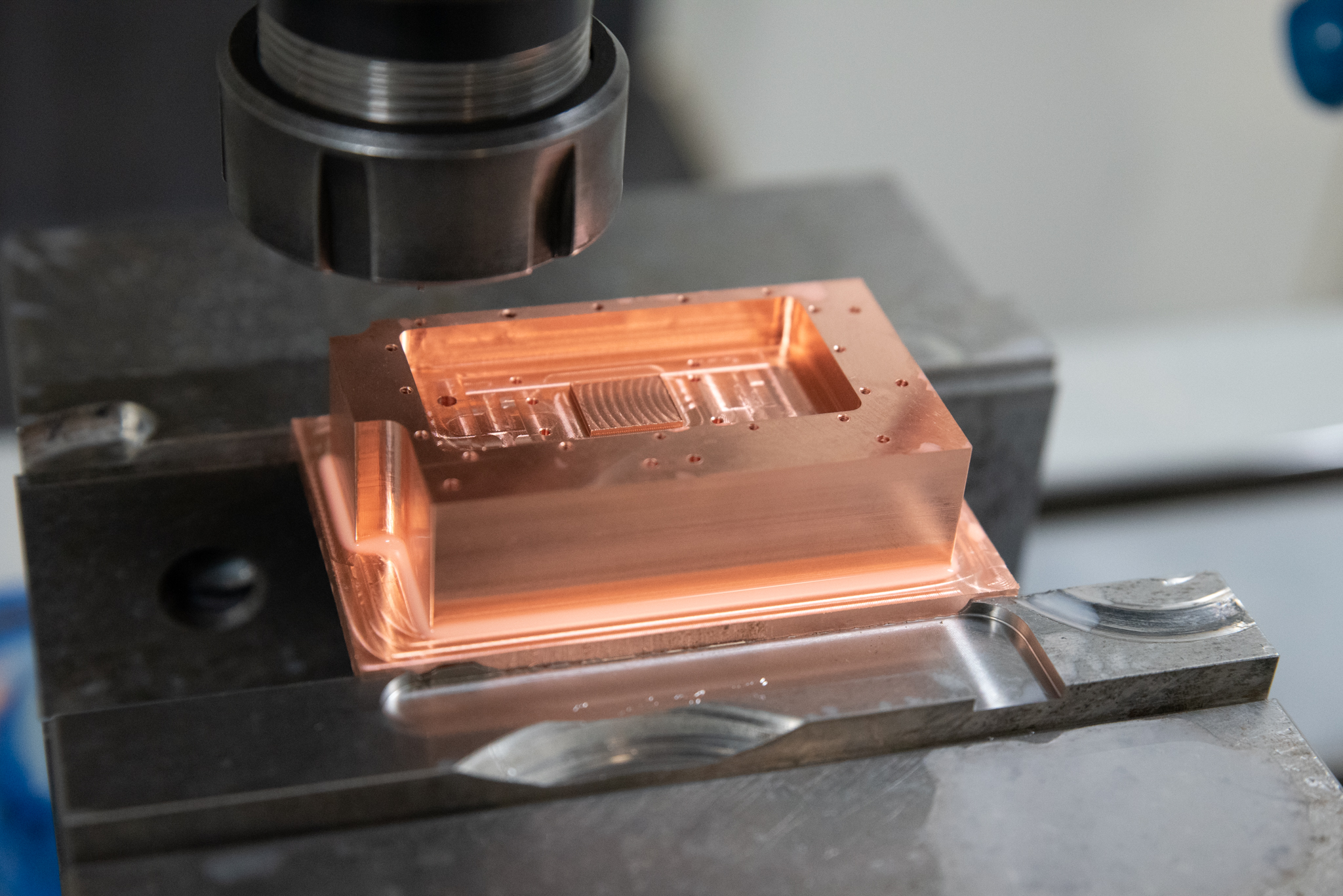

CNC EDM

Our Electro-Discharge Wire & Spark Eroders have the ability to produce very fine tolerance details in a massive range of materials, no matter how hard. We can produce splines, internal hexagons and squares, as well as very fine delicate profiles unachievable by traditional means.

Fabrication & Assembly

We can provide a bespoke fabrication and assembly service for your parts, to your exact requirements. This includes welding and sheet metal work, as well as the facility for simple to complex assemblies.

Finishing & Heat Treatment

We work alongside our IS9001:2015 approved suppliers to provide high quality finishing to your products, including all types of electroplating, heat treatments & technical coatings, painting & polishing.